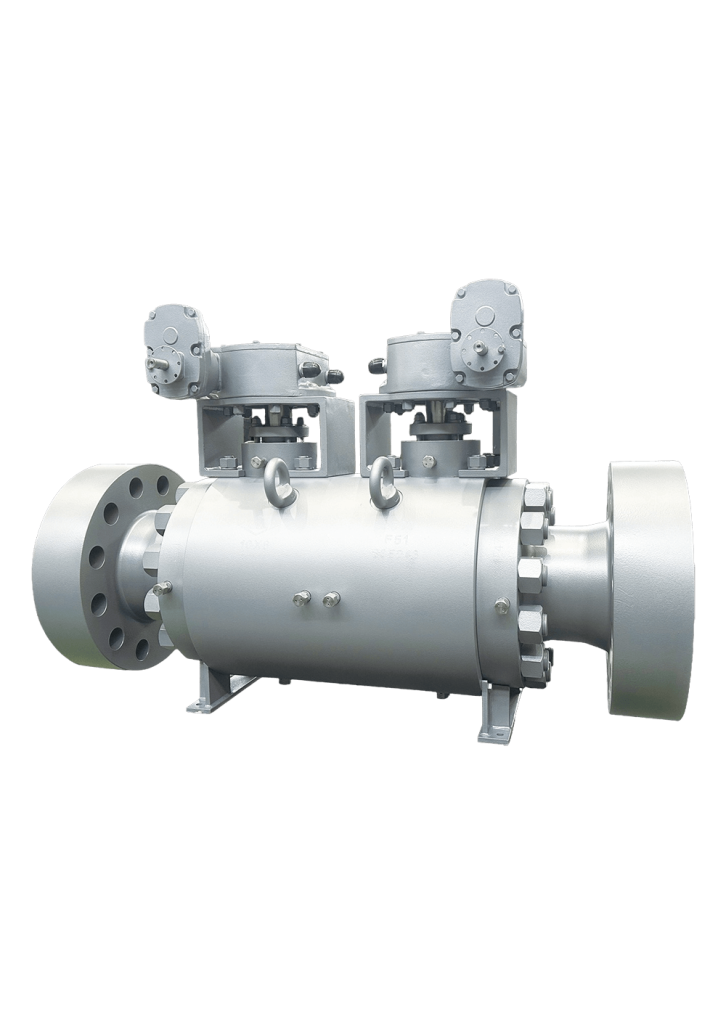

A ball valve uses a spherical ball with a central through-hole to control the flow of liquids or gases. When the valve stem rotates the ball by 90 degrees, it opens or closes the passage instantly, providing fast and reliable shut-off. Ball valves are valued for their simple structure, low pressure drop, and excellent sealing performance, making them suitable for a wide range of industrial applications. They are available in various types, such as floating, fixed, soft-seated, metal-seated, split body, top-entry, and all-welded designs.

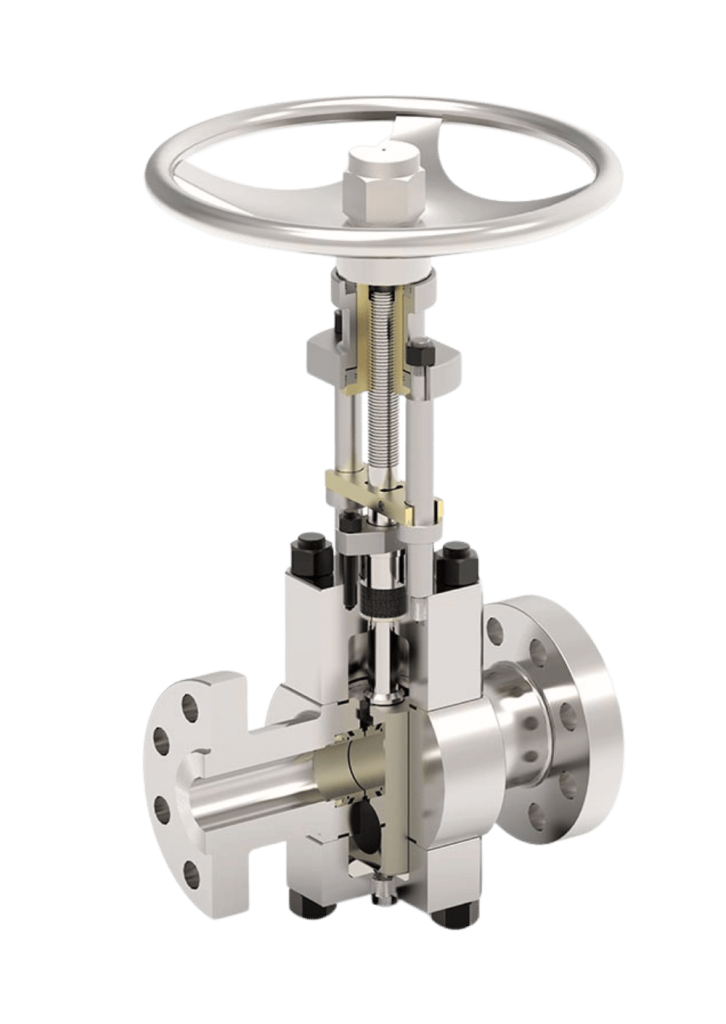

A gate valve uses a flat or wedge-shaped gate that moves vertically to start or stop the flow. When fully open, it provides an unobstructed, straight-through passage with minimal pressure loss. Gate valves are primarily designed for full open or full close applications—not for throttling—making them ideal for pipelines that require isolation. They are widely used in water supply, oil & gas, petrochemical, and industrial systems due to their dependable sealing and long service life.

A through conduit gate valve is designed with a full-bore, unobstructed flow path that keeps the bore diameter consistent with the pipeline. This design minimizes pressure drop, prevents debris accumulation, and ensures smooth pigging operations. The valve uses a slab or expanding gate mechanism that provides tight sealing in both open and closed positions. Through conduit gate valves are ideal for long-distance pipelines, high-pressure systems, and critical applications in the oil & gas sector where reliable isolation and clean flow are essential.

A butterfly valve uses a rotating disc positioned in the center of the pipe to regulate or shut off flow. By turning the disc 90 degrees, the valve quickly opens or closes, offering efficient flow control with minimal pressure drop. Its lightweight design, compact structure, and cost-effectiveness make it ideal for large-diameter pipelines and systems requiring frequent operation. Butterfly valves are commonly used in HVAC, water treatment, oil & gas, and industrial processing applications.

A check valve is a self-actuating valve that allows fluid to flow in one direction while automatically preventing backflow. It operates using a disc, ball, or swing mechanism that opens when forward flow occurs and closes instantly when the flow reverses. This design protects pumps, compressors, and pipeline systems from damage caused by reverse flow and pressure surges. Check valves require no external power or manual intervention, making them highly reliable for continuous flow operations. They are widely used in water systems, oil & gas pipelines, process industries, and applications where ensuring one-way flow and system safety is essential.

A through conduit gate valve is designed with a full-bore, unobstructed flow path that keeps the bore diameter consistent with the pipeline. This design minimizes pressure drop, prevents debris accumulation, and ensures smooth pigging operations. The valve uses a slab or expanding gate mechanism that provides tight sealing in both open and closed positions. Through conduit gate valves are ideal for long-distance pipelines, high-pressure systems, and critical applications in the oil & gas sector where reliable isolation and clean flow are essential.